The Importance of Precision in Welding Projects

Welding is a skill that requires precision and attention to detail. In the world of metalwork, even the smallest mistake can have significant consequences. This is why welders often turn to specialized techniques and tools that ensure their work meets exact specifications. One such approach is custom fabrication, which allows for personalized solutions tailored to individual project needs. This method not only enhances accuracy but also improves efficiency and quality, making it an essential practice for many professionals in the industry.

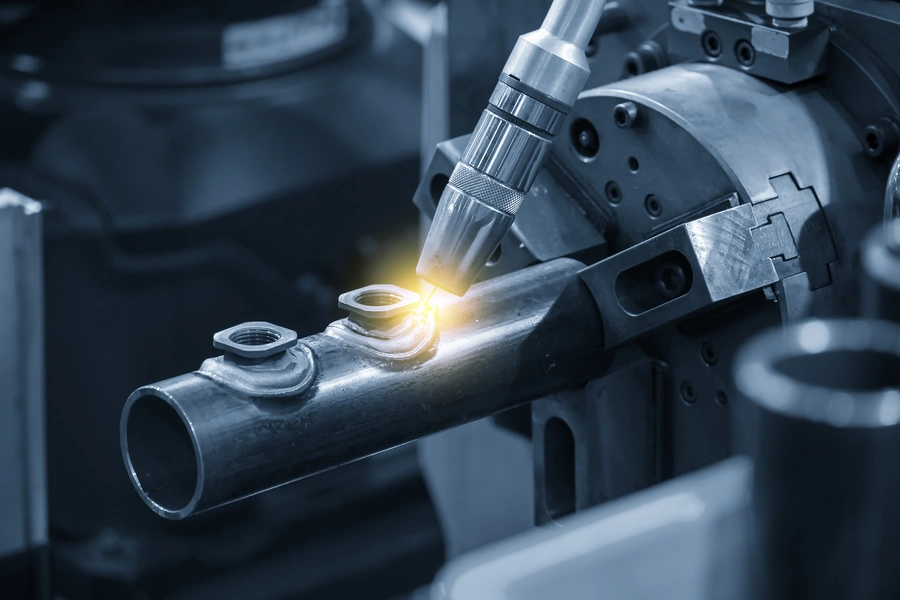

Understanding Custom Fabrication Techniques

Custom fabrication involves creating metal structures specifically designed for unique tasks or requirements. By employing custom fabrication, welders can achieve unparalleled levels of accuracy in their work. This process involves detailed planning and precise execution, ensuring each component fits perfectly within the overall design. As a result, projects benefit from increased durability and improved performance.

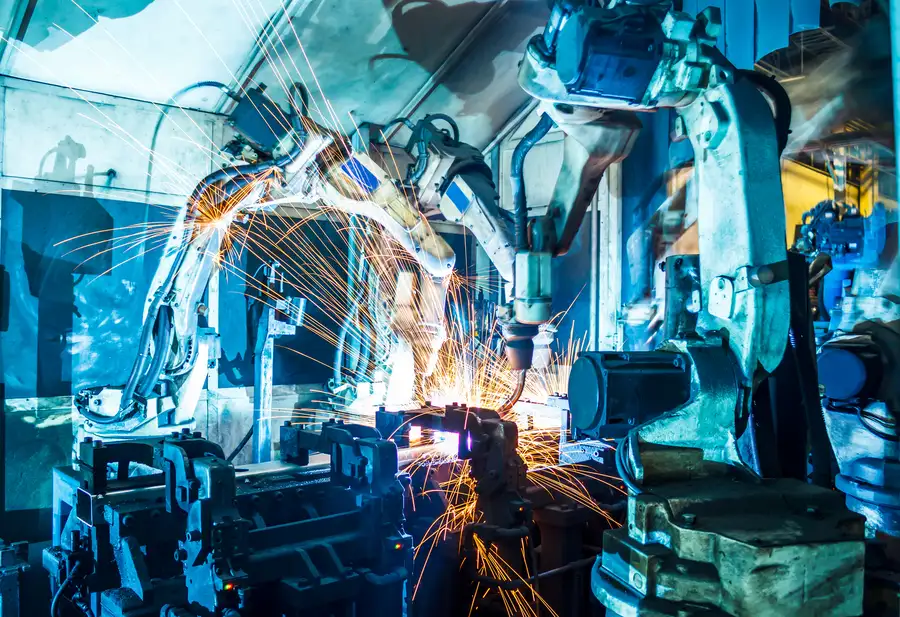

The Advantages of Tailored Solutions in Welding

There are several benefits to using custom fabrication in welding projects. Firstly, it allows for tailored solutions that meet specific client needs. Secondly, it ensures higher quality outcomes by incorporating advanced materials and technologies. Lastly, it provides flexibility in design, allowing for innovative approaches and creative problem-solving. These advantages make custom fabrication a preferred choice for many welding professionals.

Challenges Faced by Welders Without Custom Options

Without custom fabrication options, welders may face challenges such as fitting issues, material wastage, and time delays. Standard components might not align perfectly with project specifications, leading to costly adjustments or repairs. Additionally, relying on pre-made parts limits creativity and innovation in design, affecting the overall success of a project.

Steps to Implementing Personalized Welding Solutions

To implement personalized welding solutions, follow these steps:

- Assess project requirements and identify specific needs

- Select appropriate materials and tools for customization

- Develop detailed plans and blueprints for precision execution

- Execute fabrication with careful attention to detail

- Regularly test components during production to ensure quality

Best Practices for Ensuring High-Quality Results

Adhering to best practices is vital for achieving high-quality results in welding projects. Key tips include maintaining clean workspaces, using proper safety gear, and regularly inspecting equipment for wear and tear. Training staff on the latest techniques and technologies also contributes to superior outcomes.

Industry Standards That Govern Welding Accuracy

Several industry standards govern welding accuracy to ensure safety and reliability. Organizations like the American Welding Society provide guidelines that professionals must adhere to when undertaking projects. These standards cover aspects such as joint configurations, filler materials, and inspection processes, all crucial for maintaining quality workmanship.

Financial Considerations When Choosing Custom Solutions

While custom fabrication can be more expensive upfront compared to standard options, it offers long-term value by reducing errors and enhancing performance. Businesses should weigh the initial costs against potential savings from fewer repairs and faster project completion times. Investing in personalized solutions ultimately leads to higher satisfaction rates and better return on investment.

Your Go-To Resource for Precise Metalwork Solutions

If you’re looking for reliable metalwork services, I am based in Poway, CA and ready to assist with your next project. At CK Welding LLC, we specialize in providing top-tier customized solutions tailored to your specific needs. Reach out today at (858) 203-0915 to discuss how our expertise can benefit you.